Preview

5” TWO-WAY COAXIAL KIT WITH FLAX CONES

The PC 130 F is a 5” (13cm) speaker driver with a power of 60 Watts RMS.This coaxial kit is perfect for complementing the Flax component kits of the Performance Expert range. Indeed, many vehicles only have locations for 2-way component kits in the front, and full-range coaxial kits are used in the rear of the vehicle. Based on the same Flax cone technology, the PC 130 F is ideal for complementing the component kits PS 165 F, PS 165 FX, PS 165 F3 and PS 130 F to provide optimal harmonic balance.The kit is also supplied with the appropriate protective grilles.

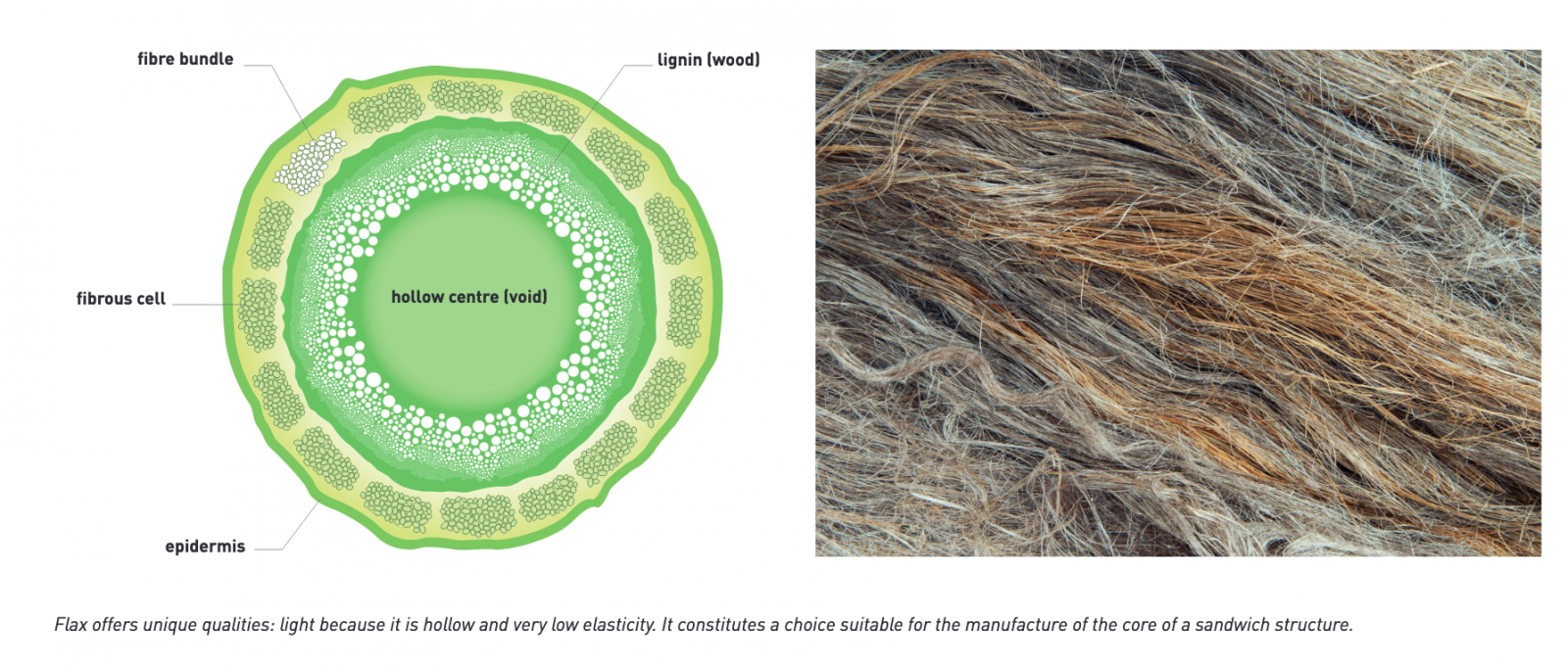

The unique qualities of flax

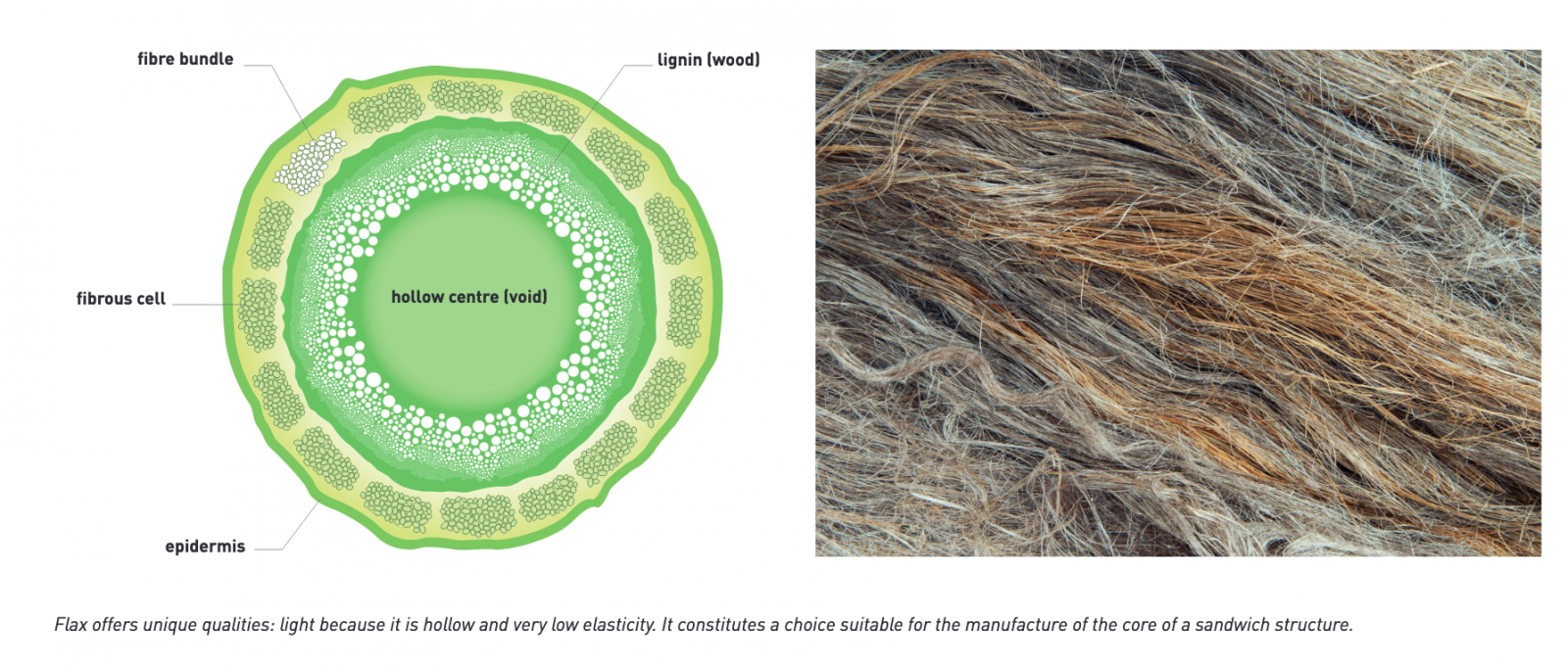

Composite materials have properties suitable for applications where both rigidity and low mass are required. However, their disadvantage is that they lack damping, which leads to very poor control of vibrations. Often, as in the case of sports equipment, it is necessary to apply damping materials to absorb the intrinsic vibration of the material. It is clear that this is a particularly critical issue for loudspeaker diaphragms, one which requires us to ensure that there is sufficient internal damping within the structure of the material. Recent developments in this field combining composites and natural fibers have brought unexpected opportunities.Flax is twice as light as fiberglass, because the fiber is hollow. It also has very low elasticity which makes it ideal to increase the flexural rigidity of our sandwich. Moreover, it can be obtained in non-woven bundles of considerable diameter and it can therefore produce the thickness required for a sandwich. Synthetic fibers or foams originating from petrochemical resources are subject to inflation linked to the sharp rise in crude oil prices. Organic or ecological textiles, like flax, are thus becoming more and more price-competitive. Flax combines the three key factors required of the core of a sandwich material for loudspeakers: it has low density, a high tensile (Young’s) modulus of elasticity of up to 60GPa, and excellent internal damping

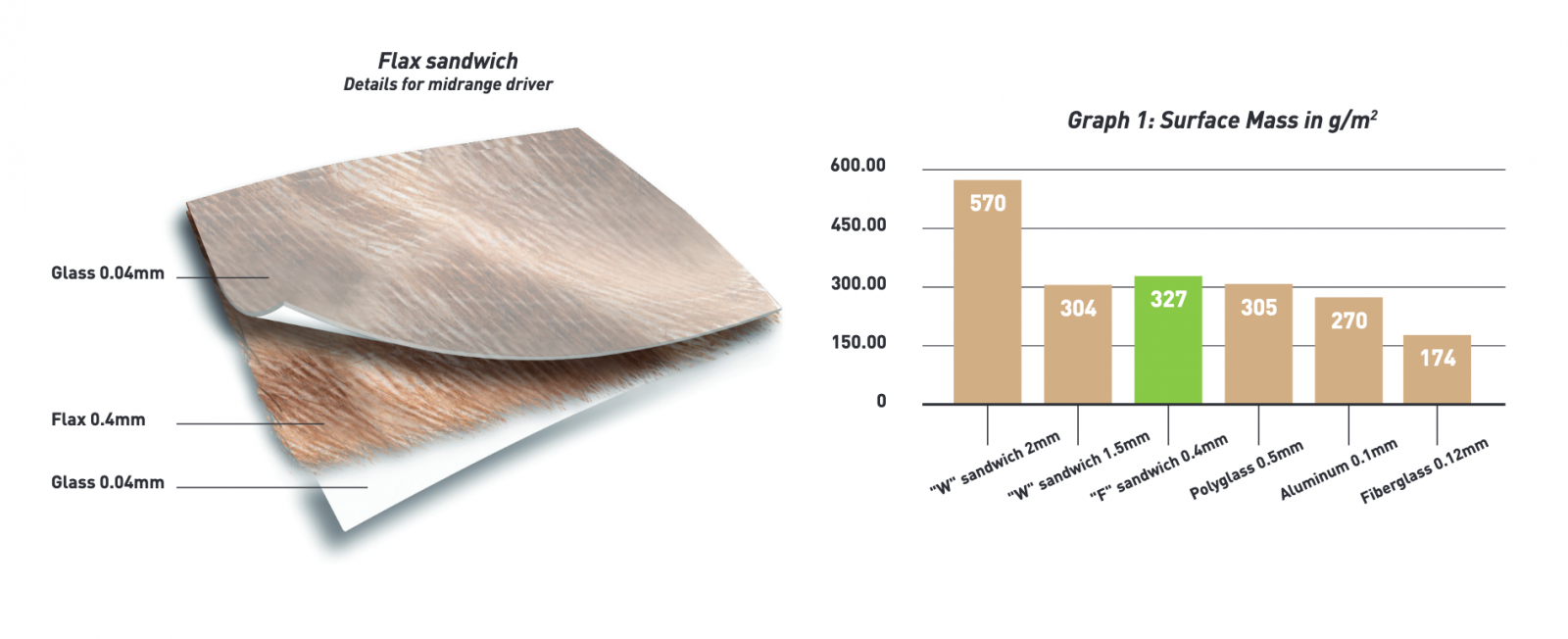

Performance comparison of various solutionsMany

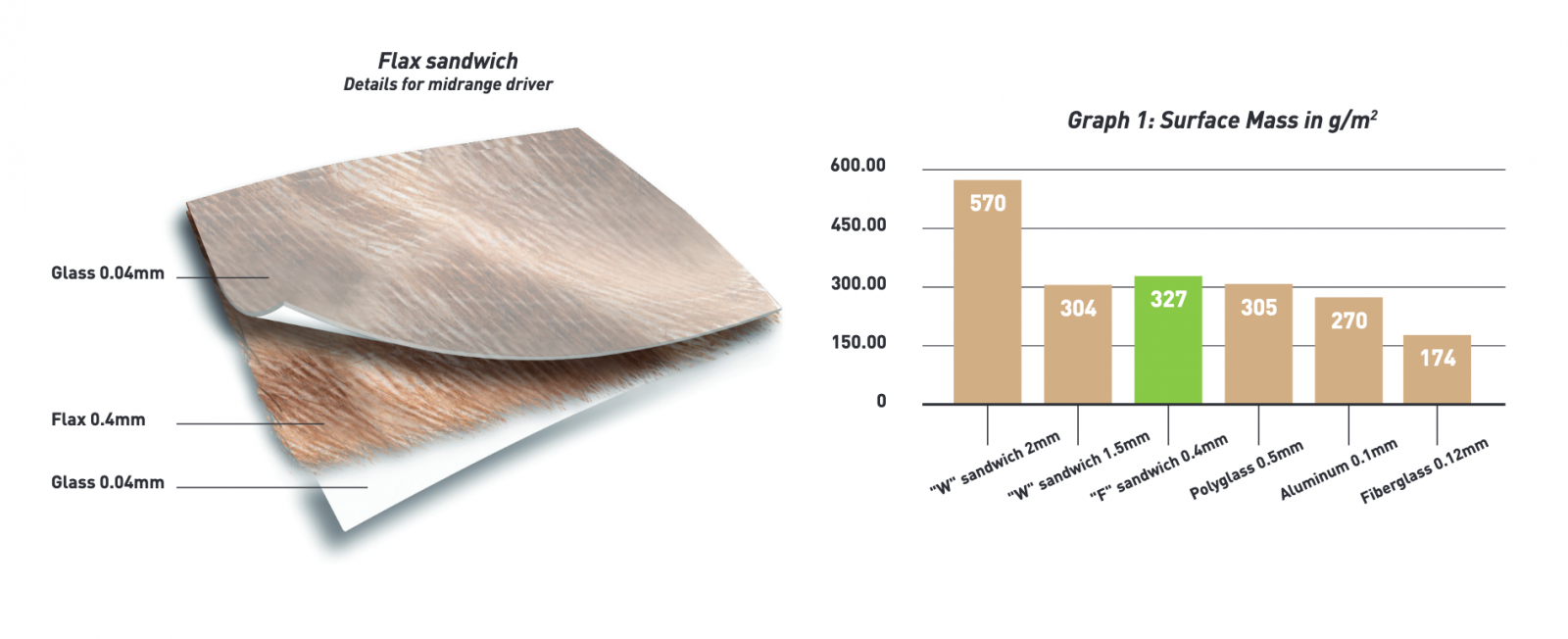

prototypes have been developed by Focal in the course of the last two years using diaphragms made from single materials (including metals and thermoplastics), composites (with thermosetting, thermoplastic and acrylic matrices) and even in coated paper. We very quickly restricted our choice to composite/sandwich structures: single-skin structures with a pre-impregnated glass fiber face and a rear woven or non-woven linen face, and sandwich structures with internal and external skins in pre-impregnated glass fiber on a core of braided or non-braided flax, with straight or semi-exponential cone profiles.A measurement report was developed internally to make our research less empirical.At each stage test samples were produced to assess the mechanical performance of the new structures. To provide reference data, test samples of Polyglass and "W" sandwich in different thicknesses, as well as aluminium and glass fiber, were also produced so that we could validate our experiments with reference to known materials.Five criteria were analysed, with results that are shown in the graphs which follow. The designations for the sandwich structures are:• "W" sandwich/Focal patent: introduced in 1995, this is a sandwich with glass fiber on both sides of a core of acrylic/Plexiglass foam.• "F" sandwich/Focal patented in 2013 (N° 1350116): this is a sandwich with glass fiber on both sides of a core of flax. It will be used in Focal products from 2013.Low mass – a guarantee of high dynamic performance[Graph 1] For a 165mm mid-woofer, the mass of the diaphragm required to conserve good sensitivity is of the order of 10 grams. This corresponds to an ideal surface mass of the order of 300g/m2. The diagram opposite shows that a 2 mmthick "W" sandwich due to its mass is more suitable for application in pure woofer. Aluminium needs to be used in a very fine thicknesses of 0.1mm, which is completely impractical. It appears in the list only to validate the coherence of our tests.

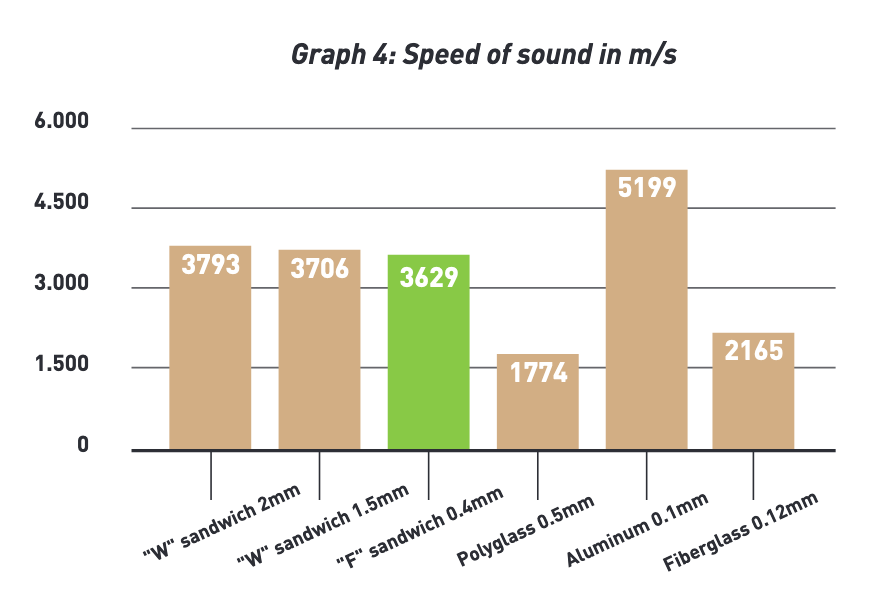

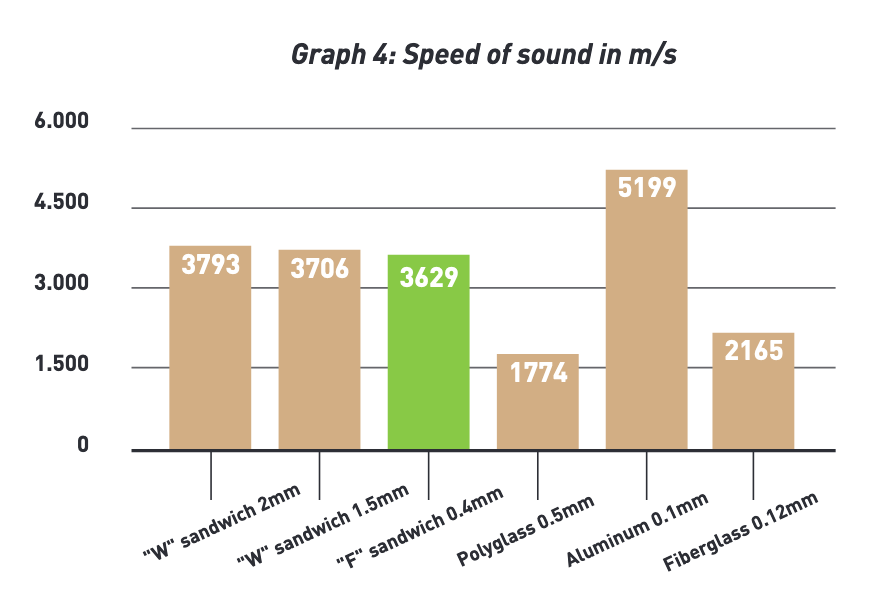

High speed of sound in the diaphragm

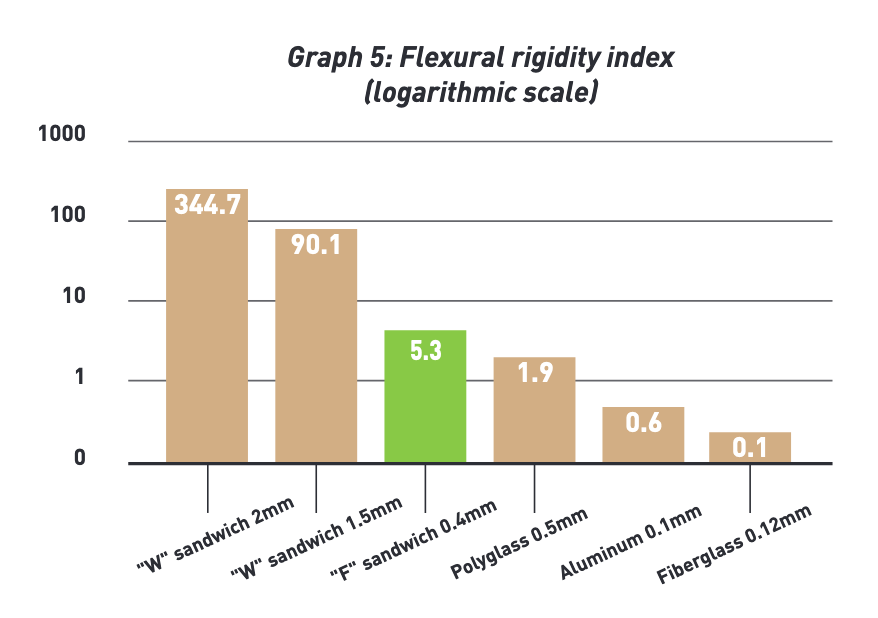

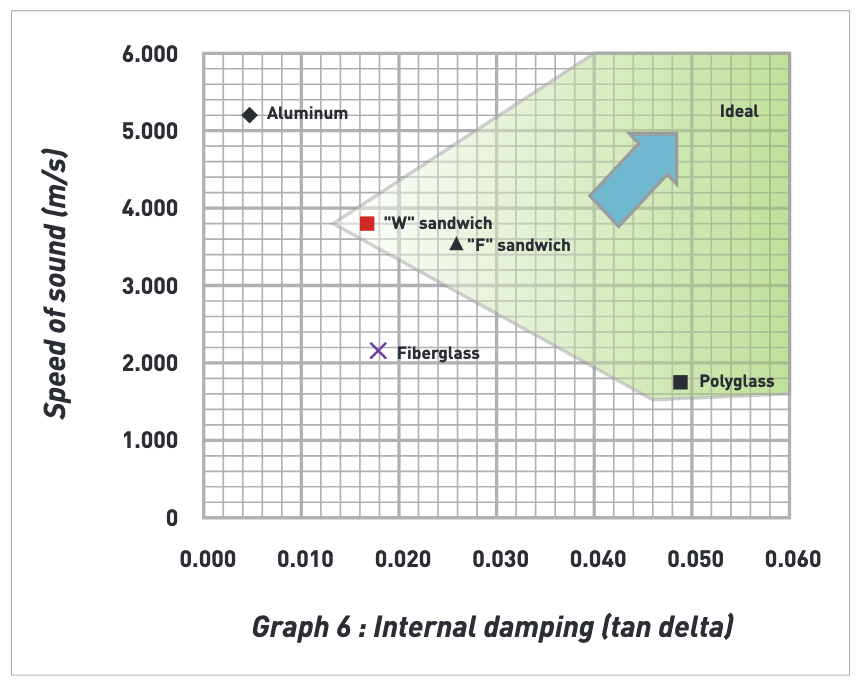

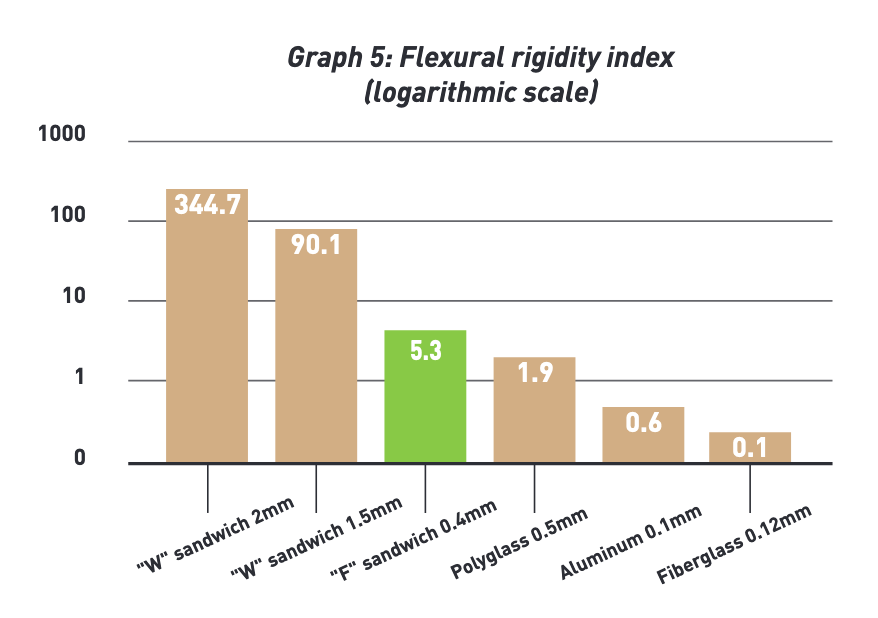

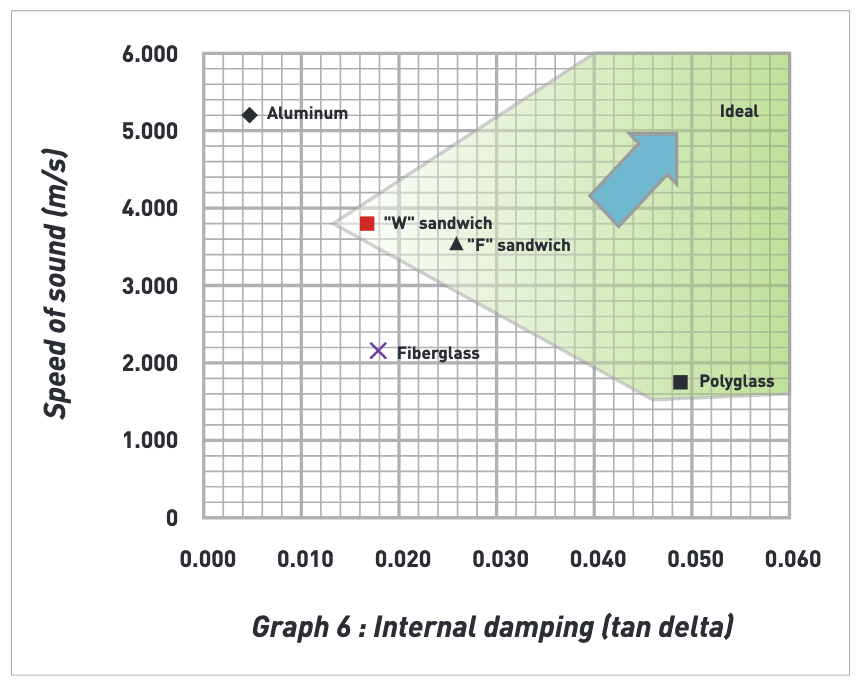

– a guarantee of definition [Graph 4] An important criterion, the speed of sound propagation in a diaphragm is directly proportional to its breakup frequency. The speed of sound of the flax sandwich is on a par with that of the “W” sandwich, with a value double that of Polyglass. High velocity of sound is also a guarantee of high definition in the midrange. Polyglass, which was introduced nearly 30 years ago, now falls far short of the hybrid materials developed by Focal in the interim.High flexural stiffness – a guarantee of well controlled bass[Graph 5] This parameter defines how stiff the diaphragm is in bending. High bending stiffness is an essential criterion for a diaphragm working at bass frequencies, where significant differences in the air pressure on either face can otherwise cause deformation. High flexural rigidity brings a material close to the theoretical ideal of a diaphragm functioning as a rigid piston over its entire passband. The advantage of sandwich construction is obvious here since flexural rigidity increases with diaphragm thickness. As the lower graph shows, the “W” sandwich is without rival in this regard. Despite its relative thinness, the flax sandwich is nearly three times stiffer than the thicker Polyglass alternative.SummaryTo design a high performance diaphragm you have to optimise a complex set of criteria, which are for the most part contradictory. The composite solution using flax in a sandwich structure with fiberglass skins is a very harmonious way of combining low mass with high internal damping, high velocity of sound and high flexural rigidity.[Graph 6]

ALUMINIUM / MAGNESIUM TWEETER

Magnesium possesses great damping qualities, Aluminum great rigidity and the two in alloy can greatly reduce distortion. This unique marriage of metals offers several advantages. The impulse response is incredibly rapid yet benefits from a very short settlement time and excellent damping. This enables the tweeter to extend its frequency response beyond 28kHz (-3dB)…

This configuration produces a precise, analytical sound and an extremely deep soundstage. The frequency response curve linearity is also remarkable in that it ensures perfect neutrality. When listening, the treble frequencies are dynamic and detailed. The Aluminum/Magnesium inverted dome tweeter then combines perfectly with the Polyglass woofer in a perfect tone synergy.

Specification

| Diameter |

5″ (130mm) |

|---|

| Voice-coil diameter |

1″ (25mm) |

|---|

| Voice-coil height |

0-3/8″ (10mm) |

|---|

| Motor |

Magnet |

|---|

| Tweeter |

Aluminum/Magnesium inverted dome |

|---|

| Cone |

Flax |

|---|

| Integrated Crossover |

6dB/Oct |

|---|

| max power |

120 W |

|---|

| nominal power |

60 W RMS |

|---|

| sensitivity |

90.5dB |

|---|

| frequency response |

75Hz – 28kHz |

|---|

| impedance |

4 Ohms |

|---|

| accessories |

Supplied grilles |

|---|